Projects

Project - Autonomous Tow Vessels for Offshore Macroalgae Farming

Sponsor - ARPA-E MARINER

Drone Tug is the farm tractor that will enable industrialized seaweed farming in the ocean. Low-cost, uncrewed, and ultra-efficient, it is well matched to key ocean-farming tasks. By exploiting the benefits of efficient, low-speed transport using large-diameter, slow-turning propellers, Drone Tug offers towing power 7-fold over conventional multi-purpose craft propulsion and a better use of labor and capital.

Drone Tug launch in Woods Hole, MA

Project - Development of Scalable Coastal and Offshore Macroalgal Farming

Collaborator - University of Alaska, Fairbanks

Sponsor - ARPA-E MARINER

The goal was to develop replicable model farms in Alaska that meet the cost criteria of less than $80 per dry metric ton of macroalgal production of sugar kelp, S. latissima.

C.A. Goudey & Associates developed an efficient, integrated seaweed farm design that has been widely adopted in Alaska.

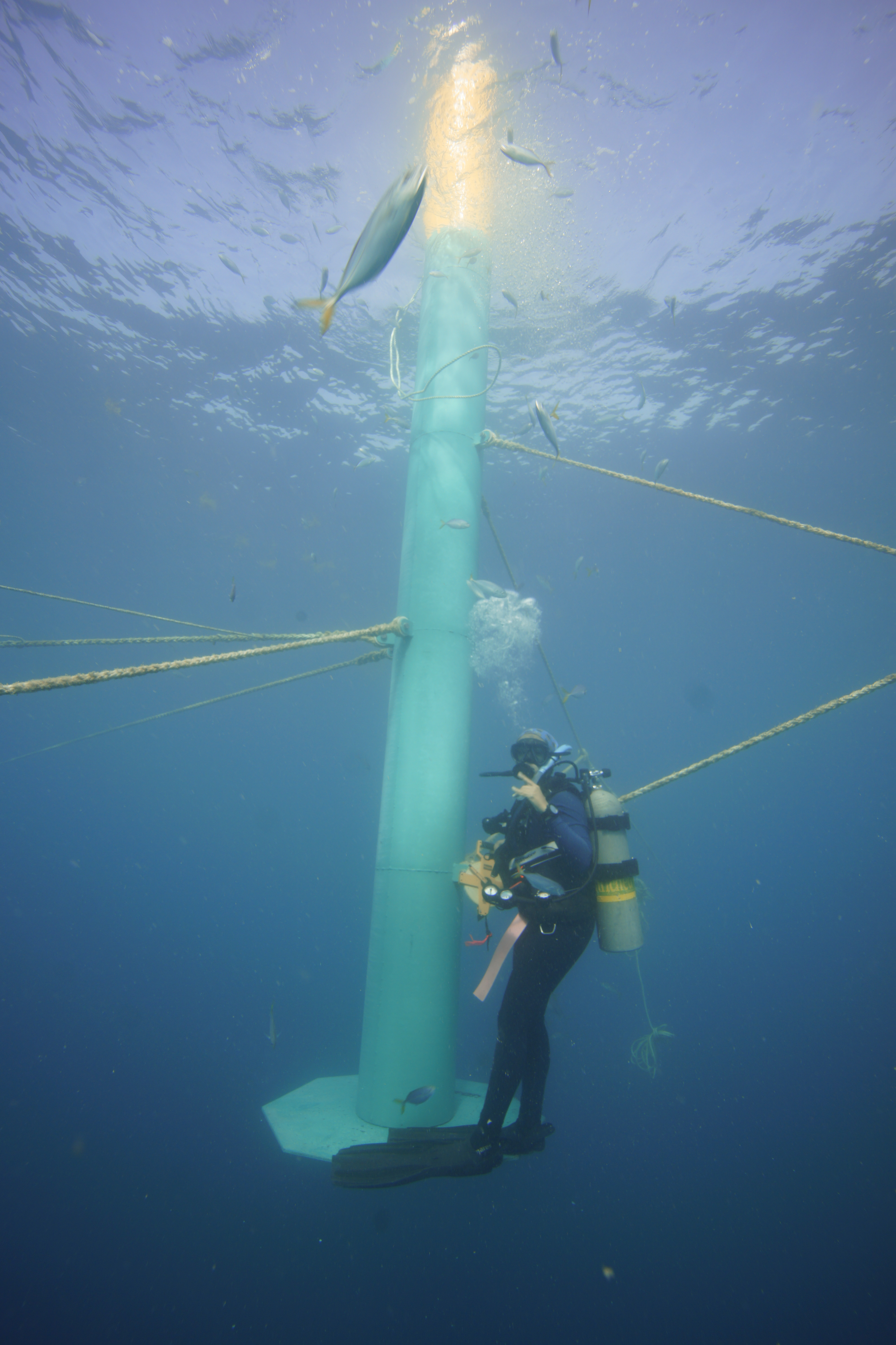

Project - Development of Techniques for Tropical Seaweed Cultivation and Harvesting

Collaborator – Marine Biological Laboratory, Woods Hole

Sponsor - ARPA-E MARINER

The project goal is the production of biomass and ecosystem services year-round using carrageenan production as a step in the pathway towards viable conversion of macroalgal biomass to fuel. C.A. Goudey & Associated designed a single-module catenary system that supported the farming of various tropical species in a location fully exposed to the Caribbean Sea.

Project – Bull Kelp farming in Humboldt Bay

Collaborator – Greenwave & Cal Poly Humboldt

In a challenging location with strong tidal currents, systems were needed to culture nereocystis as a path to re-establish natural beds. C.A. Goudey & Associates designed and installed several 5-line rigs.

Multiple system ready for deployment

Project – Mechanization of OysterGro cage flipping

Client – Mook Sea Farm

OysterGro cages are a common method of farming oysters. In order to control biofouling, the cages are flipped to allow drying out the cages to allow proper water flow to the oysters. Normal methods involve strenuous manual flipping. C.A. Goudey & Associated designed and built a powered system suspended between two hulls to flip each cage while running along the string.